ABOUT

About the surface plate

We focus on materials and durability to create safe and reliable products.

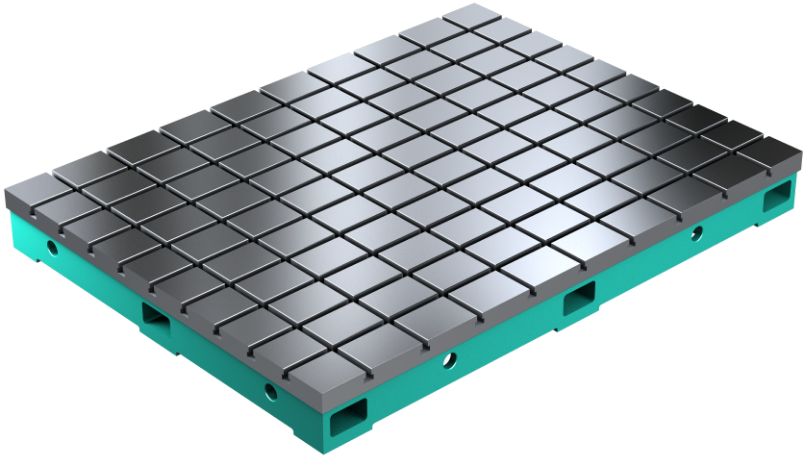

SURFACE PLATE

Surface plate

A surface plate is an important device in manufacturing and machining that accurately fixes workpieces and provides a flat surface that serves as a reference for processing and assembly, and is indispensable especially in tasks that require high precision. Surface plates, which are usually made of cast iron or steel and have a very flat surface, provide stable positioning of parts and contribute to improving processing accuracy and quality control. Surface plates are also often used in combination with measuring equipment, and function as a standard for strictly checking the dimensions and shape of parts.

KINDS

Main types of surface plate

Box-shaped surface plate

This is a surface plate with a hollow structure. It is lightweight yet highly rigid. It is mainly suitable for measuring and assembling small parts, and is easy to handle even in a small work space. In addition, the hollow structure has the effect of suppressing vibration, providing a stable measurement environment.

Precision surface plate

They are specially designed for applications that require high precision and flatness. They are used when strict dimensional measurement and shape confirmation are required in the manufacturing process. They are usually manufactured from materials such as iron or granite, and have a very smooth surface. Precision surface plates are an essential tool for inspecting molds and precision machine parts, and are an important element of quality control.

BS type surface plate

This surface plate is designed based on British Standards and is widely used especially in industrial applications. This surface plate requires strict flatness and squareness, and has high rigidity and stability. In environments where precise measurement is required, it functions as a highly reliable reference surface and plays an important role in machining and assembly work.

GRADE AND ACCURACY

Plate grade and precision

Class 2, Class 1, Class 0: The flatness of a surface plate is classified into Class 0, Class 1, and Class 2 according to the Japanese Industrial Standards (JIS B7513).

- Grade 00

- This is the most accurate grade of surface plate. The flatness error is very small, and it is used in situations where extremely precise measurement or processing is required.

- Grade 0

- This is a grade with extremely high precision. This grade of surface plate has an extremely small error in flatness and is suitable for precision measurement and advanced machining. (JIS B7513 compliant)

- Grade 1

- This is a high-precision grade of surface plate. It is widely used for high-precision machining and inspection, and is particularly useful in the manufacturing industry for quality control and precise measurement. (JIS B7513 compliant)<

- Grade 2Grade A

- This is a medium-precision grade of surface plate. It is used for daily processing and measurement work, and is the standard in many manufacturing sites. ("Class 2" is JIS B7513 compliant, "Class A" is manufacturer standard)

- Grade B

- This is the manufacturer's standard grade.

- Machine

- This is the manufacturer's standard grade.

MEASURING TOOL TYPES

Measuring tool types

Spirit level

Used to check if the surface plate is level.

Caliper

It is used to measure dimensions, allowing you to check inner and outer diameters and depths.

Micrometer

It enables high-precision measurements and is particularly suitable for measuring thickness and diameter.

Dial gauge

It is used to measure minute displacements and is particularly useful for inspecting flatness and squareness.

Coordinate measuring machine

(CMM)

Measure three-dimensional shapes and part dimensions with high precision.

Gauge blocks

Check the accuracy of other measuring tools based on specific dimensions.

protractor

Used to measure angles.

FINISHING

Finishing the surface plate

Plate finishing is the final machining stage in the manufacturing process and is an important process performed to ensure the flatness and dimensional accuracy of the plate.This finishing operation is essential for the surface plate to function as a reference surface for precise measurement and machining.

To flatten the surface of the rough machined surface plate, milling and grinding operations are used to prepare the initial shape.Next, polishing operations are performed for precision finishing.For even greater precision, hand lapping is used to remove minute irregularities to improve surface smoothness.

After finishing is complete, flatness and dimensions are checked using a digital level and CMM.This inspection determines whether the surface plate meets the specified specifications.Re-work or adjustments may be made as necessary.

Thus, surface plate finishing is an essential process to guarantee its accuracy and reliability, and is the foundation for providing high-quality products.Accurate finishing allows for greater precision and reliability in manufacturing and measurement operations.

SELECTION POINTS

Key points for selecting a surface plate

Applications

It is important to choose the right table for your purpose.

Flatness and precision

The flatness and dimensional accuracy of the surface plate are directly related to the measurement results, so check the standards (JIS, etc.)

Material

Considering the material (cast iron, stone, etc.),Consider durability and vibration absorption

Size

Choose the right size and shape to suit your workspace and the object you are working with.

Environment

In environments with rapid temperature changes and high humidity, the choice of materials is important.

Budget

Get the performance you need while staying within your budget.

HOW TO USE

How to use the surface plate

-

01

Installation

Clean the installation surface to minimize surrounding vibrations and temperature changes.

Place it on a flat, stable surface, using a spirit level to check the level if necessary.

-

02

Cleaning

It is important to clean the surface of the tabletop to remove any dust, grease or foreign matter.

Using it in a clean condition will ensure measurement accuracy.

-

03

Setting standards

When performing measurement or processing, the object is placed on the surface plate and its position is adjusted.

Determine the necessary benchmarks and confirm the location of measuring equipment and processing machinery.

-

04

Measurement or processing

Using the surface plate as a reference, measuring tools and processing machines are used to carry out precise work while checking the position of the target object.

-

05

inspection

The results are checked and, if necessary, re-measured to ensure that the results meet the standards.

MAINTENANCE

Maintenance methods and calibration

ATTENTION

Points to note about the surface plate

Checking flatness

It is important to check the flatness regularly to maintain measurement accuracy.

Beware of impacts

Be careful not to drop heavy objects on the plate or subject it to impacts to maintain its flatness and deflection.

Load management

Since the allowable load is set, do not place excessive weight on the surface plate.When placing heavy parts on the surface plate, care should be taken not to exceed the allowable load, and the parts should be placed evenly.Also, please be careful not to load workpieces when not in use.

Vibration management

It is also necessary to pay attention to the vibration in the place where the surface plate is installed. If the vibration is large, consider using a stand with vibration absorption properties.

Cleaning and maintenance

After use, always clean the surface plate to remove dirt and oil to prevent deterioration. Accumulation of dirt can affect the measurement results.

Environmental influences

It is important to understand the effects of temperature and humidity changes on the surface table and use it in an appropriate environment. In particular, environments with drastic temperature changes can cause the material to deform or warp.

Humidity control

Rust is likely to occur in humid environments, so be sure to apply anti-rust treatment and store the product appropriately. Measures against moisture are particularly important.

Regular calibration

To maintain measurement accuracy, we recommend that you perform regular calibration and have it inspected by a professional if necessary.